20. Jun

When it comes to choosing the right eyeglasses, it’s one thing to look good; it’s another to see well.

But with today’s technology in lens manufacturing, they’re one and the same. Traditional lenses for glasses may help achieve 20/20, but is your customer happy with how they look AND how they see? Digital surfacing uses the best technology available to give users the thinnest, most aesthetically pleasing alternative to clearer vision in all directions. While most lenses provide a suitable solution for nearsightedness, farsightedness, and/or astigmatism, some more complex or subtle refractive errors, also known as high-order aberrations, are where they fall flat.

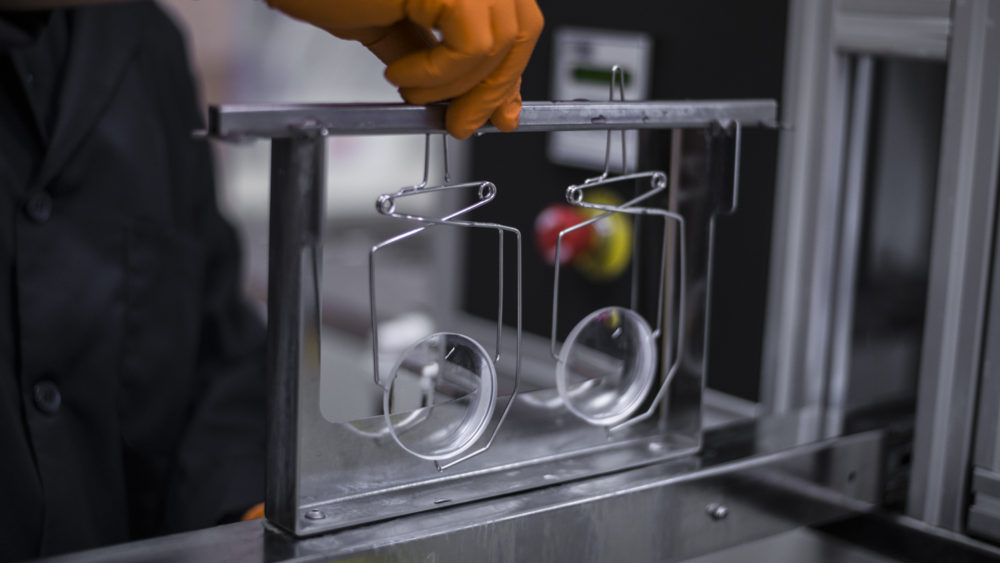

Lense fitting is no longer limited to a couple of sizes to fit all. Digital surfacing gives you the ability to create, utilizing unlimited customization options to fit the unique needs of the patient and give them a sharper vision than ever before. In fact, any issues regarding lens size or cutting are almost non-existent, so users can enjoy highly-sophisticated designs to correct any specific refractive conditions they have.

“Keep in mind that for the best vision and comfort, all high-definition lenses should include anti-reflective (AR) coating to eliminate distracting reflections,” a source from AllAboutVision.com recommends. These coatings are most beneficial when paired with digital surfacing and enable you to offer enhanced aesthetics and functionality to your customer’s new eyewear.

Digital lenses have been described as the most important improvement to eyewear in over a century. The challenge, however, may be convincing eyeglass wearers to ditch their familiar lenses and try something new. But the more they know, the more comfortable they’ll feel taking the plunge.

What are the benefits?

- 6x Improved surface precision (0.06D to 0.01D)

- More variety and design sophistication in frames and styles

- Thinnest, most comfortable lenses available

- Minimal issues with cutting or sizing and no distortion

- Half the production time of traditional lenses

The details are what really make the difference during the design process. AllAboutVision.com states, “The fabrication of some digital, free-form lenses also takes into account how the lenses are positioned in front of the wearer’s eyes when in the eyeglass frame, to provide the most accurate lens power and the sharpest vision possible.”

If there’s still any hesitation, Barry Santini from 20/20 Magazine suggests recommending baby steps. “One of the best ways to begin experiencing the benefits of free-form technology is with single-vision….Consider suggesting one of the current free-form, single-vision designs. When packaged with a quality anti-reflective coating, these lenses will produce “wows” at your dispensing desk.”

Aside from the “wow” factor, there are a number of other benefits for eye care professionals as well. By eliminating design limitations, manufacturers can offer unlimited style solutions and create the proper corrective solutions to better position themselves in the market. They can enable labs to produce higher quality lenses for more complex surfaces with less risk of error and lower costs of labor.

But according to experts at Labtalkonline.com, the most compelling benefit is for the eye care professional to position themselves for the future. As digital surfacing continues to rapidly grow, it’s essential not only to be knowledgeable on the latest in high-quality lenses but be able to provide customers with the advanced eyewear solutions they want and need.

Contact Allentown Optical today to learn more about all things digital surfacing, and to learn more about our services.