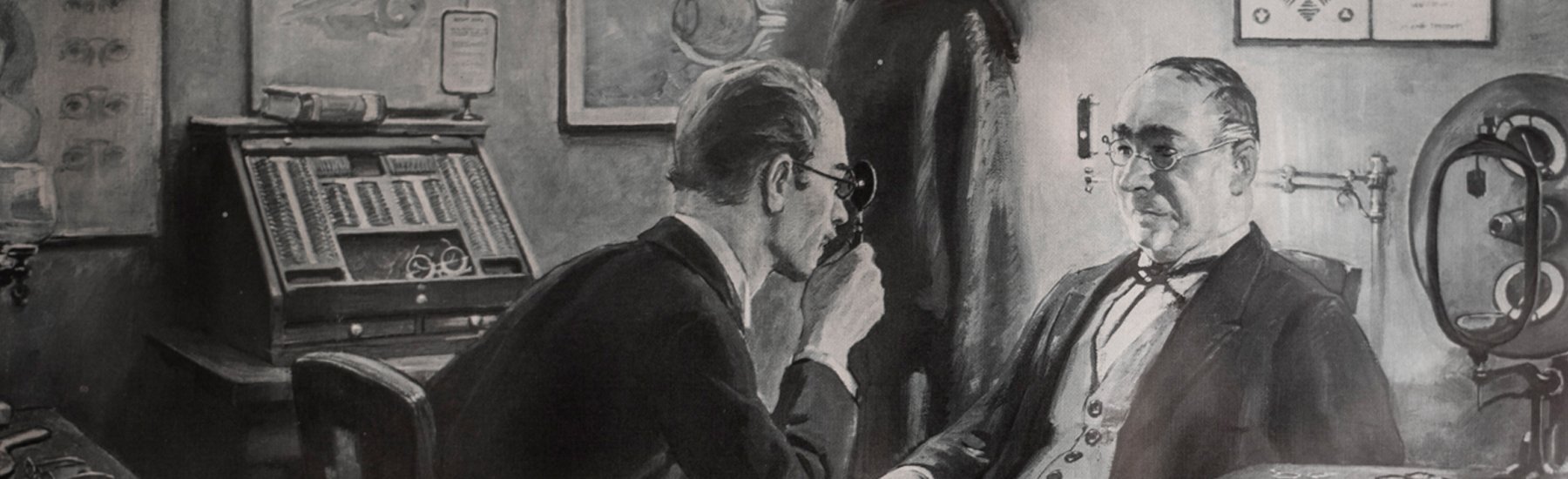

Allentown Optical is an independent optical wholesale lab serving the eye care profession for more than 35 years. Our lab is equipped with the latest in digital and AR equipment that allows us to produce lenses that create superior vision. We are committed to providing premium quality products and the best in personalized customer service.

Who We Are

What We Offer

Guaranteed Quality

We provide the best quality optical services you can find using the most modern digital technology and in-house coatings.

Modern Technology

Services include in-house AR, customized Digital Freeform lenses, drill mounts, tinting, and more.

5-Star Products

Whether plastic, hi-index or polycarb, all RX’s are fabricated to exact specifications and satisfaction.

See the Difference

Whether plastic, hi-index, Trivex, glass or polycarb, all RX’s are fabricated to exact specifications and to your satisfaction.

No RX is too difficult – high minus, slab offs or prism.

IOT Digital Ray-Path 2 Technology

IOT Digital Ray-Path 2 Technology allows for the intelligent use of the wearer’s own accommodation within the calculation methodology. In other words, in addition to taking the physical elements of the position and rotation of the eye relative to the lens into account, we now also consider the eye’s natural ability to accommodate or change focus. Patient benefits of this new technology include drastically reduced oblique aberrations across the entire visual field, greater comfort, and impeccable visual quality.